|

Service Hotline: 4006250270

|

|

Service Hotline: 4006250270

|

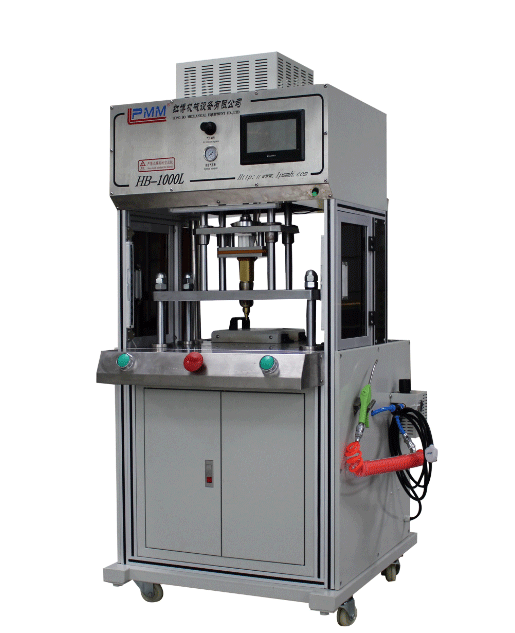

HB - 1000L one-piece top type low pressure injection molding machine

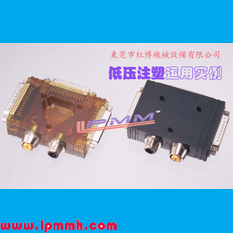

HB - 1000L one-piece top type low pressure injection molding machine 25PIN HD plug

25PIN HD plug HM101 Low-pressure injection plastic material

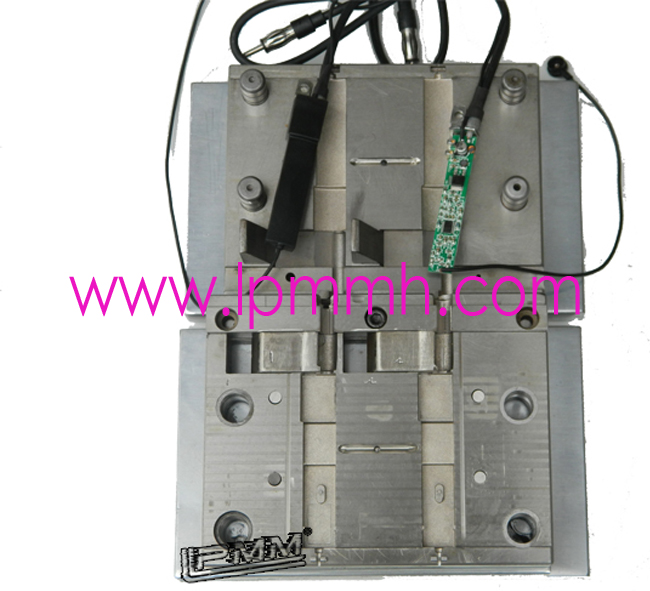

HM101 Low-pressure injection plastic material Automotive wiring harness mould

Automotive wiring harness mould HB - 900 a C custom side type low pressure injection molding machine

HB - 900 a C custom side type low pressure injection molding machine HB - 1500 rotating disc low pressure injection molding machine

HB - 1500 rotating disc low pressure injection molding machine Lateral low pressure injection molding machine of HB - 2000 double location

Lateral low pressure injection molding machine of HB - 2000 double location HB - 1200 type low pressure injection molding machine

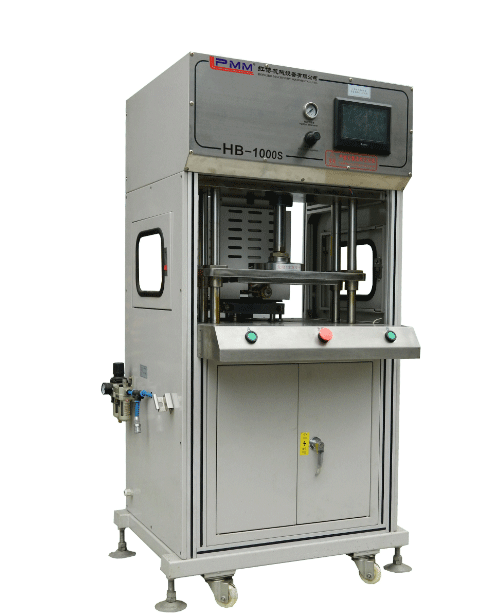

HB - 1200 type low pressure injection molding machine HB - 1000S lateral low pressure injection molding machine

HB - 1000S lateral low pressure injection molding machine  HB - 1000L split type roof type low pressure injection molding machine

HB - 1000L split type roof type low pressure injection molding machine HB - 1000 type low pressure injection molding machine

HB - 1000 type low pressure injection molding machine HB - 800 low pressure injection molding machine

HB - 800 low pressure injection molding machine Cooperation with the customer

Cooperation with the customer Car battery jig

Car battery jig Car battery jig

Car battery jig

Car battery jig

Car battery jig

4006250270

RedBo Machinery Co Ltd.

Contact:24小时服务电话:13922511557

电话:0769-87980202

Tel:4006250270

Tax:0769-87986585

Emial:联系邮箱:HONG.YANG2008@163.com

Address:The jewel of Dongguan city Tangxia town B Jiao Tang gem Industrial Zone, Road No. 25

Production and marketing in the country among the world's major mold, the largest number of mainland die at home and the number of employees, almost seven state-owned enterprises, foreign-funded enterprises account for the majority, a large number of mold factory employs about 600 to 700 people, more companies scale up to thousands of people and medium-sized mold factory is between 150 to 300 people, a small mold factory is also at least 50 people, in other countries die industry is mostly small and medium enterprises operating patterns.

In product category, 2002 in Japan and mainland emphasis on the production of stamping die and plastic mold, both the proportion of the total value of up to eighty percent, South Korea and other places mold largest proportion of output, total output value of four to seven. In the application market, Japan, Korea, the United States and Germany as the largest automobile mold products, and our form of electronic communication products used mainly die.

1, with the development of the aerospace and defense industries, the microelectronics industry, modern medicine and bio-engineering technology. Demand for precision / ultra-precision parts (feature size in micron to millimeter level) is increasingly urgent. The specific shape of the structure, diversification of parts and materials, dimensions and surface quality have become the salient features of high-precision high-precision parts and micro-devices and equipment, in the use of function, material properties, structural shapes, reliability, etc. the requirements are also increasing.

At present, precision machinery manufacturers exist in Western countries and some higher level of economic development in developing countries and regions (such as Singapore, etc.). Customers are mainly present in these regions.

2, China's high-precision machinery manufacturing technology in the late 1980s and early 1990s was gradually developed, China today is a rapidly developing industry. High-precision machinery manufacturing products are widely used in national defense, medical, aerospace, electronics and other military civilian areas.

3, precision machinery manufacturing and general machinery manufacturing compared to products with high technological content (design and production), processing equipped, high added value, low-volume sales mostly differentiated features.

Low pressure injection mold

4, low pressure injection molds high precision parts manufacturing is a high precision machine parts for the processing of objects. The use of systematic, integrated theory and technology, feed, processing, testing, handling and other organic combinations and optimized according to the workpiece structure and requirements, to complete the production of parts in precise processing conditions. Its purpose is to achieve the "small machining small parts" concept, is different from the ordinary manufacturing methods and techniques of mechanical parts. It will be the processing of non-silicon materials (such as metals, ceramics, etc.) the most effective high-precision parts machining methods. Precision instrument parts can solve problems of processing methods fundamentally. With high precision, low energy consumption, production flexibility and high efficiency advantages. Reduce the size of the entire manufacturing system and the size precision parts, both to save energy and save manufacturing space and resources to meet the energy-saving, environmentally friendly mode of production. Is one of the development of green manufacturing.

"Unless noted, content rests Dongguan Hongbo finishing, reproduced, please indicate the link and source」

News